Products

NGK ELECTRONICS DEVICES, INC., by mobilizing the technological capabilities and product development capabilities of the NGK Group, creates excellent electronics products that make contributions to the society.

Thanks to various ceramics materials and outstanding technological capabilities that have been developed in the course of electronic component manufacturing for long years, we provide a wide variety of products that meet the customers’ needs and make contributions to the society.

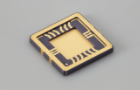

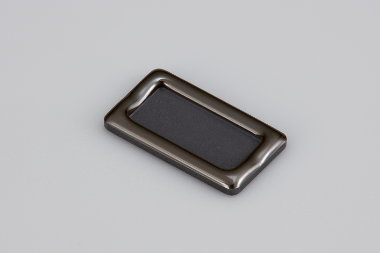

Products for timing device

Ceramics products for communication devices that support the foundation of the digital society

A timing device generates electric signals (clock signals) at accurate and constant intervals that serve as the reference for matching the timing of signal transmission/reception by multiple electronic circuits. It is an indispensable component for continuing normal operation of a communication electronic device such as smartphone and PC. The main materials serving as the source of these signals are crystal and ceramics. The ceramic packages we provide protect fragile crystal elements from the outside environment with their excellent airtightness, heat resistance, and strength, and support stable data communications.

For the information on the products,

contact us via the following.

- Tokyo Sales Division 03-6779-5050 FAX:03-6779-5030

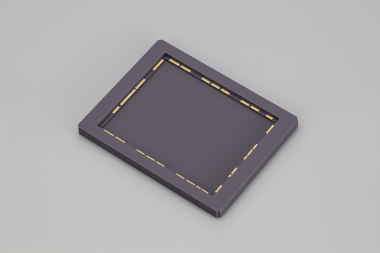

Products for imaging device

Ceramic packages for imaging element that address the advancing image processing technologies

Imaging devices enable high-resolution imaging and are employed in digital single-lens reflex cameras, surveillance cameras, FA appliances, car-mounted devices, inspection devices, AR and VR devices, and others. Among them, image sensors known as CCD and CMOS turn sensed lights into electric signals to draw images, as if they were electronic eyes, and are the most important components that greatly affect the image quality and performance of camera. Recently CMOS devices that are operated at lower power and purchased at lower prices have become the mainstream, and their performance is further improving and usage further expanding. We achieve weight reduction, high reliability, high thermal dissipation, and other features by means of our own ceramics technologies, making contributions to performance improvement of COMS.

For the information on the products,

contact us via the following.

- Tokyo Sales Division 03-6779-5050 FAX:03-6779-5030

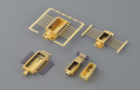

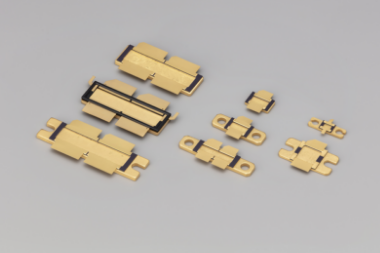

Products for high-frequency power device

Ceramics products that support wireless communication data traffic that keeps increasing and becoming faster

High-frequency devices are indispensable for amplifying radio signals to allow safe and smooth transmission/reception of radio waves, and are employed in wireless communication infrastructures including base stations for mobile phone and satellite communications as well as in automobiles as radar for measuring distance between cars. In these days when the data communications become faster and larger in volume, what is required of those devices is to prevent cross talk while maintaining high output. The ceramic packages we offer support improvement of the performance and efficiency of high-frequency radio devices by means of high thermal dissipation, high reliability, and high flatness and make contributions to the data communication infrastructures in the contemporary society.

For the information on the products,

contact us via the following.

- Tokyo Sales Division 03-6779-5050 FAX:03-6779-5030

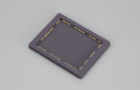

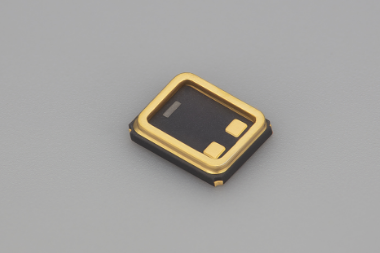

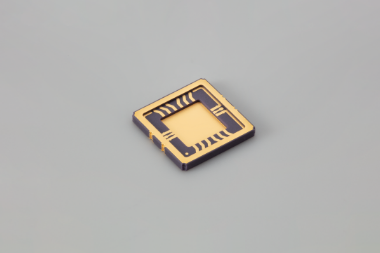

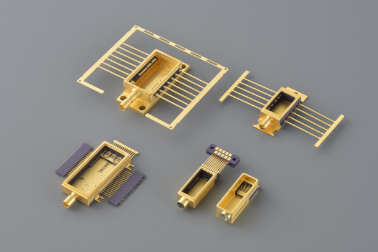

Products for optical communication device

Ceramic packages applicable to high-speed communications that support optical communication network infrastructures

Optical communication devices are key devices that support the optical communication network, which is indispensable for communication infrastructures including the Internet and IoT. The device employed in the converter unit for optical fiber communication in which electric signals are converted into optical signals is an optical communication package. The ceramic packages we offer protect the semiconductor element from outer environment and, by dissipating the generated heat, maximize the performance of the semiconductor. Furthermore, our devices have achieved high reliability, downsizing, and low cost thanks to their improved density by means of ceramic multi-layered substrate, and support high-speed broadband data communications demanded by the contemporary society.

For the information on the products,

contact us via the following.

- Tokyo Sales Division 03-6779-5050 FAX:03-6779-5030

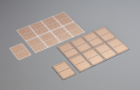

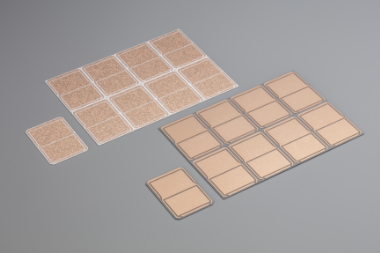

Products for power module

Ceramic substrates for power semiconductor that make contributions to realization of carbon-free society

A power module is a component in which a large-capacity power circuit consisting of combined multiple power semiconductors for electric power supply concerning driving motor and battery is constructed in a compact manner. Against a backdrop of the shift to electric automobiles, with the competition for power module development intensifying, our AMB Substrates for Power Modules using ceramic materials efficiently release heat generated in the power semiconductor and provide electric insulation, thus making contributions to the advancement of the performance of inverter control devices.

For the information on the products,

contact us via the following.

- Tokyo Sales Division 03-6779-5050 FAX:03-6779-5030

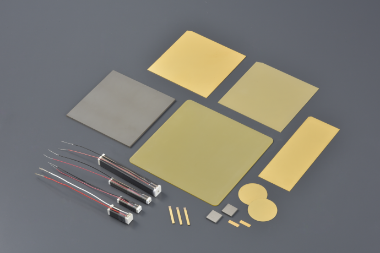

Products for ink-jet printer

High-density piezoelectric ceramics products that support printing technologies

An ink-jet printer performs printing by directly spraying ink. Our piezoelectric ceramic materials with a high density and an excellent processability are used in the ink-jet heads and support the high-speed performance, high image quality, and high durability of ink-jet printers.

For the information on the products,

contact us via the following.

- Tokyo Sales Division 03-6779-5050 FAX:03-6779-5030

Other products

For the information on the products,

contact us via the following.

- Tokyo Sales Division 03-6779-5050 FAX:03-6779-5030